Q624A1014/U

Product Description

APPLICATION

The Q624A is a solid state spark generator (transformer) for use on commercial or industrial gas burners.

FEATURES• Ignites gas pilots with spark gaps up to 1/4 inch (6 millimeters) in length.• 15,000 volts peak voltage for reliable lightoff.• Prevents detection of the ignition spark when properly applied in a flame detection system with the C7027,C7035, or C7044 Minipeeper® or C7061 Dynamic Self-Check Ultraviolet Flame Detector.• Ignition spark and ultraviolet detector are synchronized by the alternating current supply voltage; spark occurs on one half of the ac cycle and detector operates on the opposite half cycle.• Recommended for interrupted ignition applications only.• Mounts in the same space used by conventional ignition transformer.• Q624 mounting holes are the same as standard transformers; no adapter plate needed.• Impervious to humidity up to 95 percent relative humidity.• Weighs 3 pounds (1.4 kilograms) versus 8-1/2 pounds (3.9 kilograms) for standard transformers.

Table 1 SPECIFICATIONS

IMPORTANTThe specifications given in this publication do not include normal manufacturing tolerances. Therefore, this unit may not match the listed specifications exactly. Also, this product is tested and calibrated under closely controlled conditions, and some minor differences in performance can be expected if those conditions are changed.

| Electrical Ratings | |

| Voltage and Frequency | 120 Vac, 50/60 Hz. |

| Output Voltage | 10,000 volts |

| Primary VA Rating | 66 VA at 120 Vac. |

| Spark Characteristics | |

| Firing Rage | 60 sparks per second. |

| Voltage, peak-to-peak | 22,000 volts nonsinusoidal. |

| Firing cycle peak voltage | 15,000 volts ±500 volts, open circuit. |

| Energy Discharge | 200 millijoules per spark. |

| Discharge Time | 0.3 milliseconds per spark. |

| Power Dissipation | approximately 12 watts per second. |

| Maximum High Voltage Lead Length | 15 ft. (4.6 m) |

| Maximum Spark Gap | 1/4 in. (6 mm) |

| Ambient Temperature Range | -40°F to +125°F (-40°C to +52°C) |

| Maximum Ambient Humidity | 95 percent RH. |

| Type of Service | All types of gas ignition; not recommended for use when igniting oil. |

| Mounting | Surface |

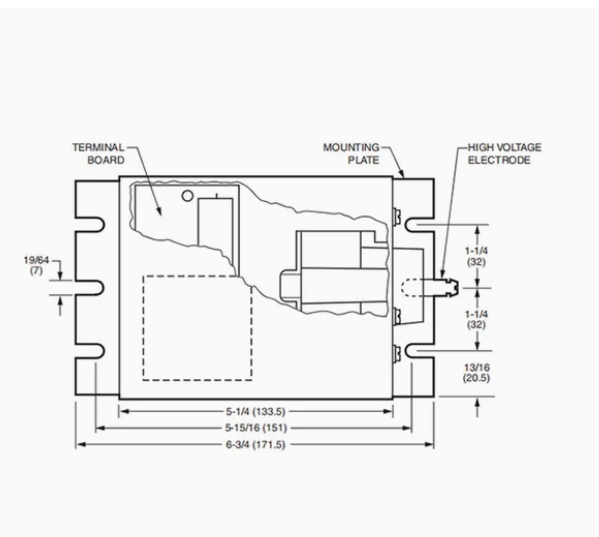

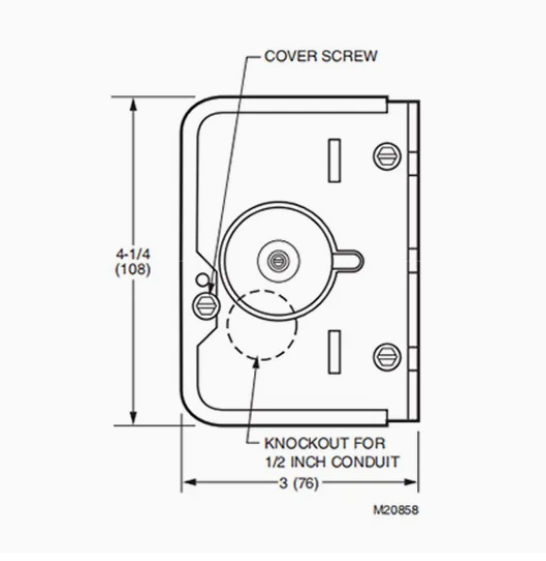

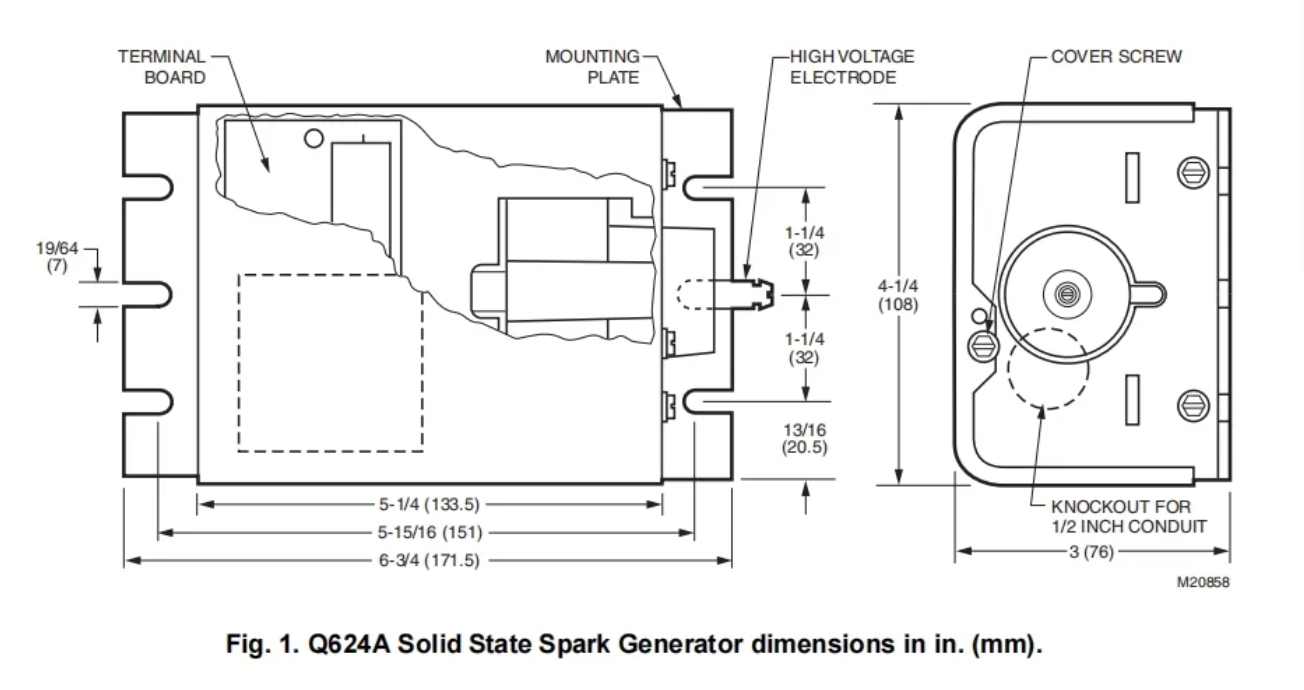

| Dimensions | See Fig. 1. |

| Weight | 3 lb. (1.4 kg). |

| Approvals | Underwriters Laboratories Inc. Component Recognized: File No. MH7453, Guide No. JHYR2; tested and accepted for use in ambient temperatures ranging from -40°F to + 125°F (-40°C to +52°C).Canadian Standards Association Certified: File No. LR95329. |

| Accessories | C7005 Gas Pilot, with ignition electrode.Q179 Gas Pilot, with ignition electrode.134666 Insulator; may be used to cover terminal, to prevent contamination, and to give added terminal protection.32004766-001 24 in. (610 mm) Ignition Cable Assembly.32004766-002 120 in. (3.05 m) Ignition Cable Assembly.32004766-003 Ignition Cable (per foot, specify required length).32004766-004 60 in. (1.52 m) Ignition Cable Assembly. Cable should be rated for 25kV at 482°F (250°C). |

INSTALLATION

When Installing This Product…

1. Read these instructions carefully. Failure to follow them could damage the product or cause a hazardous condition.

2. Check the ratings given in the instructions and on the product to make sure the product is suitable for your application.

3. Installer must be a trained, experienced, flame safeguard control technician.

4. After installation is complete, check out product operation as provided in these instructions.

Mounting

The Q624A mounts in the same space required by a standard ignition transformer, using the same mounting holes. It may be mounted in any position.

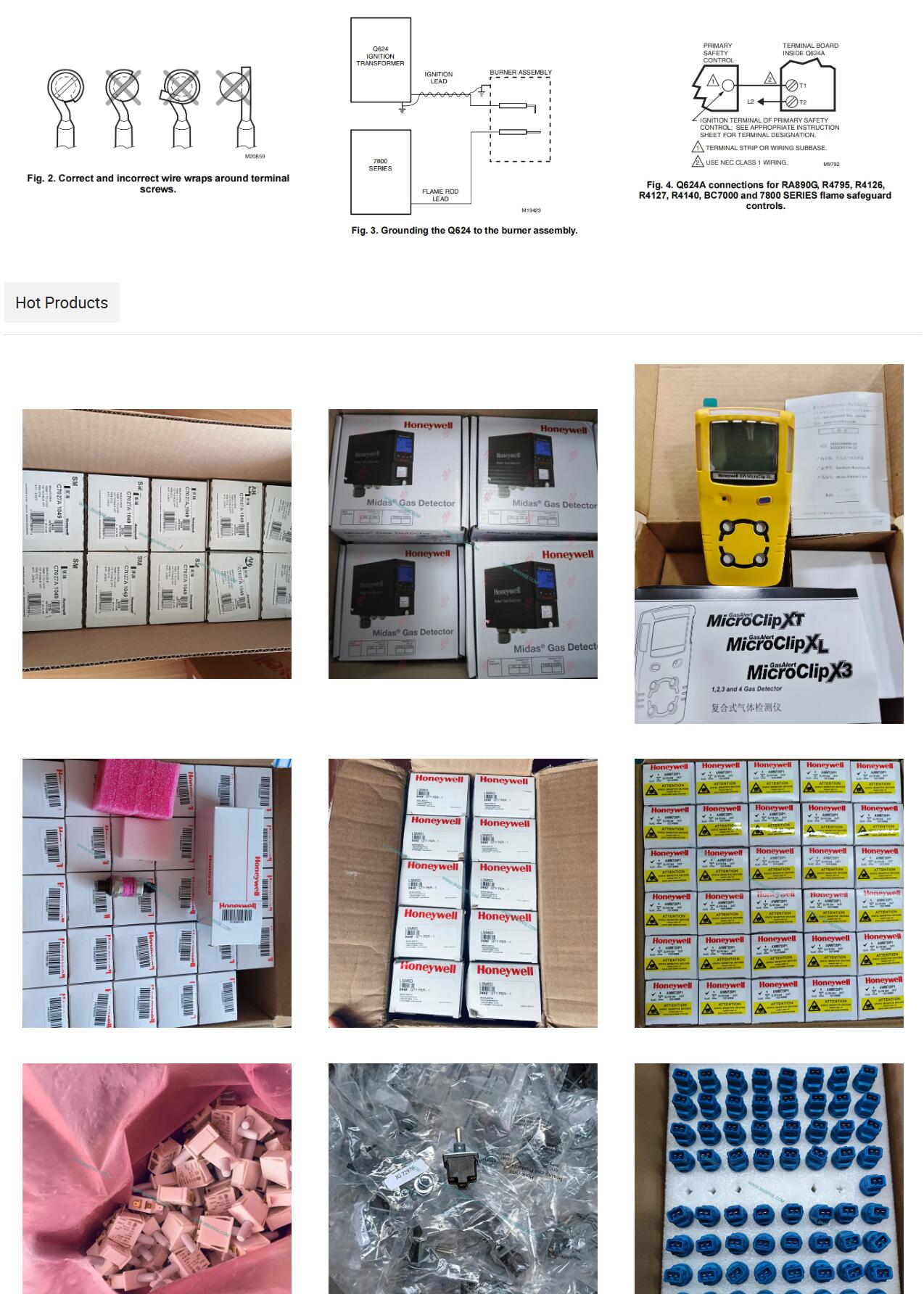

1. Loosen the cover screw (FIg. 1) and remove the cover.2. Insert two leads (NEC CLass 1) through the 1/2 in. (13 mm) conduit knockout (Fig. 1) and connect them to the screw terminals on the terminal board, and to the

terminal strip or wiring subbase of the flame safeguard control (see Table 2 and Fig. 3 or 4).3. Replace the cover and tighten the cover screw.

4. Connect the high voltage electrode (Fig. 1) to the ignition electrode on the pilot burner, using the appropriate Ignition Cable Assembly or Ignition Cable (see Accessories in the Specifications section).

IMPORTANT

The ignition cable should not exceed 15 feet (4.6 meters) in length.

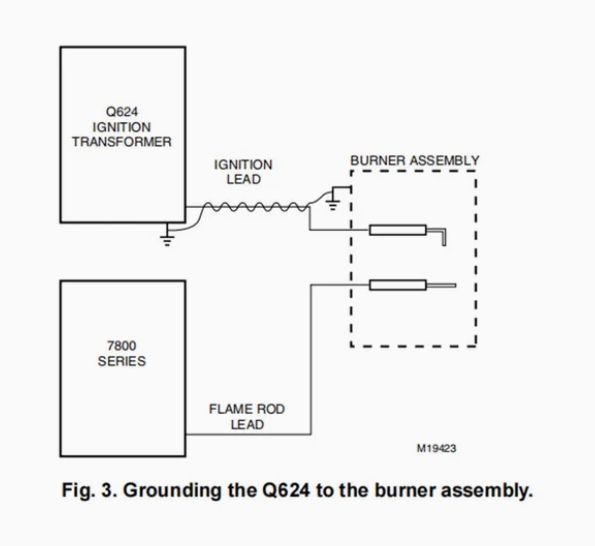

To ground the Q624 to the burner assembly:

1. Use a No. 16 or No. 18 wire.

2. Attach one end of the wire to the Q624 ignition transformer end (GND).

3. Wrap the wire around the igniter (high tension) lead as shown in Fig. 3. Four or five wraps are sufficient.

4. Connect the other end of the wire to the burner assembly (GND).

Table 2 Wiring Connections.

| Flame SafeguardControl Model | Q624ATerminal | Flame Safeguard Control Terminal | ||||||||

| RA890G and R4795 | T1T2 | 4L2 | ||||||||

| R4126, R4127,R4140, and BC7000 | T1T2 | Appropriate ignition terminalas specified on programmerinstruction sheet.L2 | ||||||||

| R4150 | T1T2 | L2Appropriate ignition terminalas specified on programmerinstruction sheet. | ||||||||

| RM7800 | T1T2 | 10L2 | ||||||||

BNSENS (Nanjing) Sensor Technology Co., Ltd. is located in Nanjing, China. It is a high-tech enterprise specializing in the development, manufacturing and trade of sensor products. The company has brought together a group of outstanding technical experts in various fields such as automation, electronics, machinery and computers. All employees of the company have college degrees or above. It adopts the world-class management and operation model and 6 sigma quality system. At present, the company's main products are pressure, liquid level, flow, current, switches, etc. The company's users are all over the country, and some products have been exported to Japan, South Korea and Southeast Asia.

Since its inception, the company has been based on the technical accumulation and management standards of American sensor giants. It is composed of senior engineers and managers who have served in multinational companies for many years, and has rapidly developed various pressure sensors, transmitters, liquid level, flow meters, pressure switches, digital meters, current sensors, proximity switches and other products. After years of unremitting efforts, it has become one of the leading suppliers in the domestic automation industry. Our pressure transmitters can achieve an accuracy of more than 3/10, 000. The products have been widely used in oil, natural gas, electricity, chemical industry, metallurgy, building materials, food, light industry, environmental protection, aerospace, tap water, municipal and other industries.

It is a sensor science and technology innovation company that masters the core technology of MEMS chips. The company has a research and development center in Minnesota, USA. The leader is Dr. Pan Hanjin, a famous scientist in the sensor industry. Dr. Pan Hanjin has been deeply involved in the sensor industry for more than 20 years and is an expert in the sensor industry.

The company has a number of ASIC chips independently developed, which are widely used in industrial, automotive, home appliance and other markets.

BNSENS (Nanjing) Sensing Technology Co., Ltd. is a strategic partner of Honeywell in China. The two parties proposed a plan of East serving East and jointly developed several sensors specifically for the Chinese market. These sensors will be widely used in intelligent manufacturing, Internet of Things, artificial intelligence, and smart home fields. These sensors include: Magnetic sensors, temperature sensors, humidity sensors, force sensors, fire water pressure sensors, equipment vibration sensors, human body status monitoring sensors, motion sensors, etc.

History of BNSENS Company:

BNSENS is a company focusing on sensors, instruments, and electronic components. We are a young company, founded in 1999, just 25 years old, and we are still growing.

1999: The company's first pressure sensor was launched, mainly for the petroleum and petrochemical industries.

2002: The company expanded its product line and launched temperature sensors

2005: Started producing high-precision pressure sensors for the test and measurement market

2006: Became an official authorized agent of Honeywell

2009: Introduced the Six Sigma management system, and the product qualification rate was greatly improved

2010: Became a supplier of Emerson

2011: We started selling SICK sensors

2014: Introduced the sensor production line from Germany, developed more industrial control sensors, and cooperated with TSMC

2015: Cooperated with Siemens in Vietnam

2017: The factory moved to Nanjing High-tech Zone

2019: Became a national high-tech enterprise in China

2023: We started selling products from Infineon and Rohm

BNSENS, The Future Starts Here.