Analysis of Compressible dustbin detection system based on ultrasonic sensor

With the continuous improvement of our environmental governance system and the continuous promotion of the modernization of environmental governance capacity, the development concept of "innovation, coordination, green, open and sharing" has gradually taken root, and people are pursuing a higher quality of life. New smart cities are also given birth, and urban development has been given new connotation and new requirements. According to the country's garbage growth curve released by the National Bureau of Statistics and the OECD, the annual total amount of garbage is about to exceed 300 million tons. Garbage has become one of the main culprits that destroy the urban environment and reduce the quality of people's life. The problem of urban garbage has gradually attracted wide attention from all walks of life. The accumulation of garbage will cause the breeding of bacteria and viruses, posing a non-negligible threat to people's normal life.

With the rapid development of Chinese urbanization, solving urban garbage problems has become the most important task in order to create a harmonious and beautiful urban environment, the reform of garbage bins is the key step. There are all kinds of problems in traditional garbage bins, which lead to the situation of excessive load of resources and waste of resources. The dustbin control system proposed in this paper, in order to adapt to the development of The Times as the theme, improve the quality of people's life for the purpose, through the control of mobile phone to achieve the location of the dustbin, dustbin capacity detection, garbage in the dustbin compression and the dustbin has been full of reminders and other functions.

The invention and research of compressible dustbin is of great significance for creating harmonious and beautiful urban environment and promoting social development. Compared with traditional garbage bins, compressible garbage bins use advanced integrated circuits, sensors and other technologies to realize intelligent garbage compression, which can compress garbage quickly, scientifically and timely, and is more compatible with the production efficiency of garbage in modern society. Today, with the rapid increase of labor costs, compressible garbage bins can collect garbage more efficiently and send reminders when full, so as to make the resource allocation of sanitation workers more reasonable and realize the allocation and utilization of resources.

1 Basic Concepts

The main technology used in this paper is ultrasonic ranging and compression system device.

1.1 Ultrasonic Ranging

The working principle of ultrasonic ranging is that the ultrasonic transmitting probe is used to continuously emit acoustic signals, and the reflected wave is reflected back after encountering obstacles. The receiving probe receives the reflected wave signal and converts it into a telecommunication signal [5]. In this paper, the acoustic signal is used to judge whether the capacity of the dustbin has reached a critical state. The MCU continuously detects the echo reflected by obstacles after ultrasonic transmission, thus measuring the time difference T between transmitting and receiving echoes, and then calculating the distance S=C×T/2, where C is the wave velocity of ultrasonic wave in the air medium.

This design is by the control timer to generate ultrasonic pulse and start the internal counter to start time, the electrical signal into ultrasonic signal. By calculating the round-trip time difference between ultrasonic transmission and reception, the measured distance is obtained, and the LCD displays the distance, so as to achieve the purpose of measuring the distance. When the distance is less than the received signal, the circuit sends out a signal that can be compressed and transmitted to the compression system, which completes the purpose of this paper.

1.2 Compression System

The compression system device receives the signal transmitted from the ultrasonic ranging system to compress the garbage in the garbage box, so as to improve the utilization rate of the garbage bin. The compression system adopts a connecting rod mechanism. Through analyzing the motion and power of the mechanism, relevant structural design and strength and deformation analysis are carried out to achieve the objectives designed in this paper [6]. By connecting the ultrasonic sensor to detect the height of garbage in the trash can, obtain the feedback signal, and then control the electric telescopic rod to move back and forth, and realize the compression plate on the volume of garbage compression.

In this paper, the design concept of the compression structure is to save space, the compression area is large, and the electric telescopic rod can be controlled to compress the garbage. The specific requirements for the telescopic machine are:

(1) The motor provides energy.

(2) The final motion form presents straight motion in the vertical direction.

(3) The linear motion of conversion should be uniform, and the speed should not be too large.

(4) The overall structure should occupy less space when it stops compression [7].

2. Design structure of compressible dustbin

2.1 Structure of garbage compression device

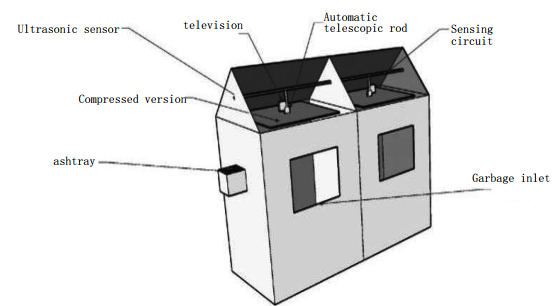

Garbage compression device is the executive device of compressible dustbin. It receives signals transmitted by ultrasonic sensors for feedback, and thus compresses objects in the garbage bin to a certain extent. The main structure of the device is structural frame, induction system and compression system [8].

In the framework, this paper uses a column as a channel between ultrasonic sensor and compression device sensor, which contains lines for information transmission; At the top of the dustbin, a piece of pressure plate almost equivalent to the area of the dustbin mouth is used as the compression plate to compress the garbage. The specific compression length depends on different dustbin models.

The receiving system of the device uses machine language, receives the signal transmitted by the sensor, compiles it, and then feeds it back to the compression system to achieve the purpose of saving space by compressing garbage in this paper. In this paper, the preliminary design of the compressor can reach a huge pressure of 75 kN, can cope with most of the compressible garbage and will not cause damage to the dustbin, as shown in Figure 1, at the bottom of the dustbin added induction device, in the dustbin to reach the key point immediately stop compression, and call the sanitation workers to clean the dustbin inspection.

Figure 1 System structure of the compressible intelligent dustbin

2.2 Structure of ultrasonic ranging sensor

The compressible bin incorporates an ultrasonic ranging sensor. Ultrasonic ranging device placed in the bin pole, to ensure that the bin does not reach 75% capacity, ultrasonic signal time is consistent.

Once the time changes, can detect that the trash can capacity has been more than 75%, need to send a signal to the compression system, the motor pull down the compression plate compression to the trash can capacity of 50%; When the bin reaches 90% capacity, start the motor again and compress to 75%.

Because the ultrasonic ranging module is relatively simple, it is more convenient in the process of implementation. As shown in Figure 2, the ultrasonic module is programmed by C++ language and implemented by 51 microcontroller

3. Design of wechat mini program

The main functions of the new dustbin small program include: the identification of dustbin model, dustbin place display, dustbin dynamic capacity detection, the execution of the compressed garbage request, dustbin other data display.

After starting the mini program, the user can enter the main page, which has two interfaces of recognition and capacity.

On the recognition screen, you can enter the bin model or automatically identify and query the device information. As shown in Figure 3, click the complete collection of Dumpster models to know the detailed information of different dumpster models.

In the capacity interface, there is a prompt saying "First compress the garbage when it is full", below which you can enter the number of the garbage bin, as shown in Figure 4.

(1) Click on the location to view the location of the garbage bin.

(2) Click the box to display the capacity data inside the dustbin.

(3) Click the compression garbage, you can execute the compression command, increase the capacity of the dustbin.

(4) Click the data, and you can detect the data information of ultrasonic sensor, compression structure, Bluetooth module, and the number of dustbin cleaning history.

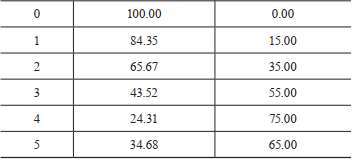

4 Test the detection system

The capacity of compressible dustbins in different time periods is measured by the increase of the time of putting and the amount of garbage. The measured results are shown in Table 1. The test results show that the error between the measurement data of the dustbin capacity obtained from the ultrasonic ranging induction device system and the actual storage data of the dustbin is within a reasonable range, which meets the needs of experiment and application.

7d9be835-4db9-4c90-bb94-b07c8393d5df.png

Table 1 Test data of the new dustbin No.1 trial release

5 Conclusion

In this paper, a compressible bin capacity detection system based on ultrasonic sensor is proposed. The purpose of this system is to enable the supervisor to directly obtain the dynamic capacity data of the bin, so as to facilitate the operation of garbage compression. Intelligent garbage can be compressed system, ultrasonic ranging system, is a new product of machine, electricity technology, improve the utilization rate of garbage can, more user-friendly wechat small program let people better use intelligent garbage can. Today, with the gradual improvement of labor cost and intelligence, the system rationally allocates sanitation workers to clean up garbage, improves the utilization rate of sanitation personnel, and realizes the rational allocation of personnel and public resources. To a certain extent, the design of compressible garbage bins makes up for the deficiency of traditional garbage bins. It is believed that compressible garbage bins can improve the efficiency of urban garbage treatment. Further improve the urban service level, so as to build a harmonious and beautiful city.

[Reference]

[1] Zang Weiming, Li Yuefang, Wei Guangming. The framework and evaluation index of new smart city standard system [J]. Journal of China Academy of Electronics Science, 2018 (1) : 1-7.

[2] Chen Yougang, Wang Xianzhou. Review on the treatment technology of municipal solid waste [J]. No.1 Technology, 2010 (1) : 1-4. (in Chinese)

[3] Yang Lei. Design and Research of Mobile Waste Compressor [D]. Qingdao: Shandong University of Science and Technology, 2017.

[4] Wang Yuxin, Liu Hong, Yao Junhao, et al. Design of "Smart City" Dustbin Based on STM32F103zet6 Control [J]. Electronic World, 2019 (2) : 136-137.

[5] Song Suyang, Zhang Wenyuan, Zhang Jie, et al. Design of intelligent ultrasonic ranging System based on MCU control [J]. Integrated Circuit Applications, 2019 (5) : 113-114. (in Chinese)

[6] Lin Lin, Guan Feng, Zhang Fei, et al. Structure Design and Mechanism Analysis of Self-clamshell Compression Multifunctional Intelligent Garbage Can [J]. Mechanical Engineer, 2016 (4) : 98-100.

[7] Zhao Tianfei, Wang Hongxiang. China Science and Technology Information, 2013 (12) : 170-172.

[8] Tong Cong, Li Shuangyue, Li Tingting, et al. Design of Experimental Platform for Compression Deformation Characteristics of Domestic Refuse Box [J]. Machinery Design & Manufacture, 2012 (3) : 31-33. (in Chinese)