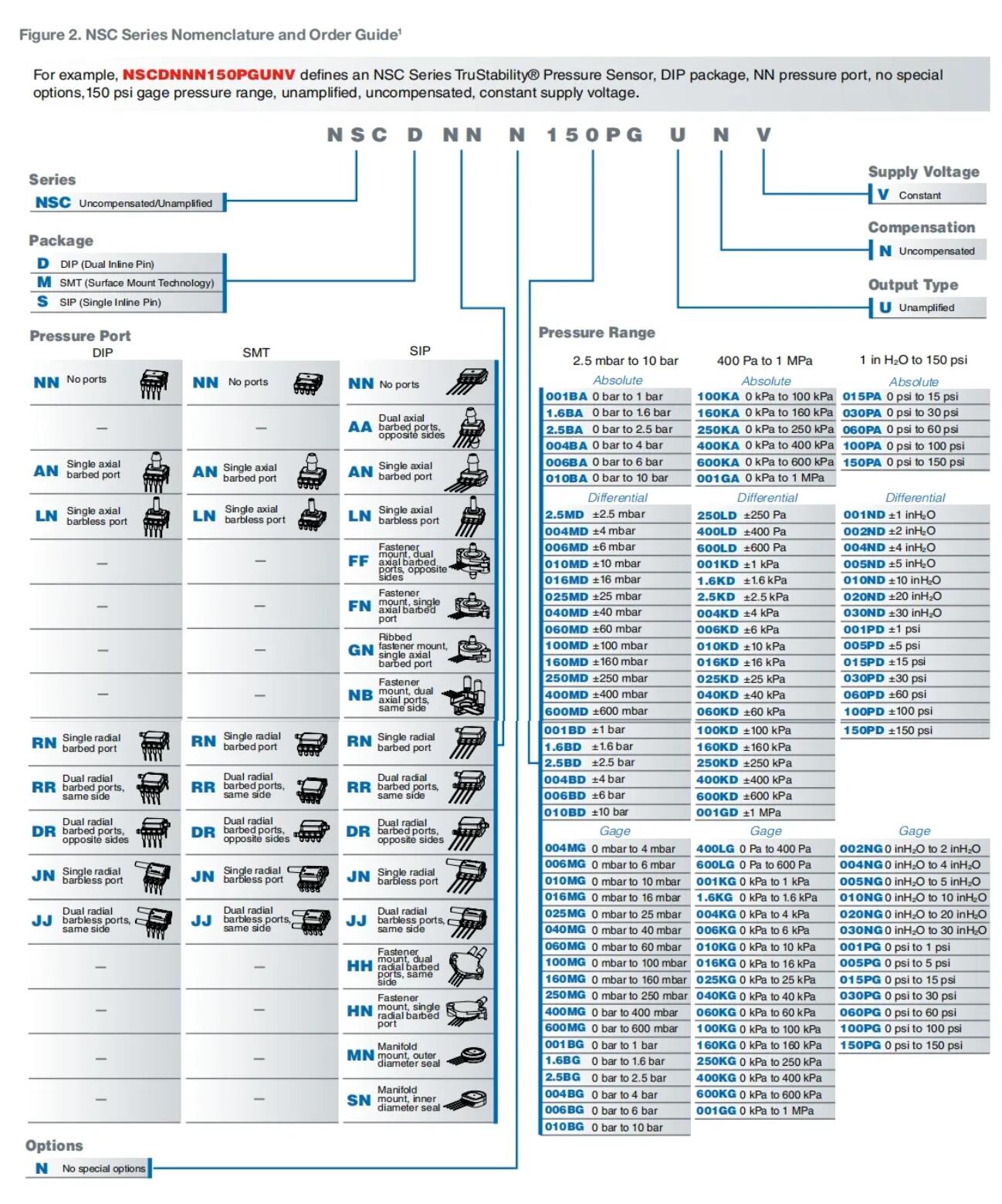

NSCSJJN030NDUNV

Product Description

DESCRIPTION

The Honeywell TruStability® TSC Series and NSC Series are piezoresistive silicon pressure sensors offering a ratiometric analog output for reading pressure over the specified full scale pressure span and temperature range.

NSC Series

• Uncompensated and unamplified

• Allows customers the flexibility of performing their own calibration while still benefiting from the industry-leading stability, accuracy, and repeatability that the Honeywell TruStability® Pressure Sensors provide

• Operates as specified from -40°C to 85°C [-40°F to 185°F]

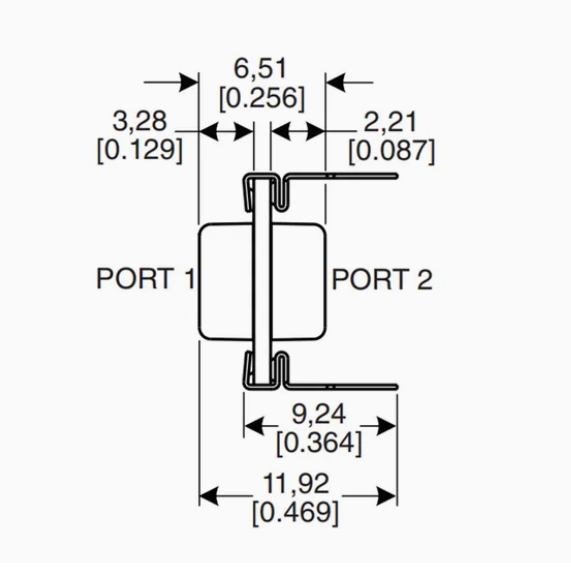

• Measures absolute, differential or gage pressuresThe absolute versions have an internal vacuum reference and an output value proportional to absolute pressure.

Differential versions allow measurement of pressure between two pressure ports. Gage versions are referenced to atmospheric pressure and provide an output proportional to pressure variations from atmosphere.

The TSC Series and NSC Series sensors are intended for use with non-corrosive, non-ionic gases, such as air. Port 1 can also be used for non-corrosive, nonionic liquids on sensors rated above 60 mbar | 6 kPa | 1 psi.

The TSC and NSC Series offer numerous package styles and mounting options, making it easier for device manufacturers to integrate the product into their applications. These sensors offer infinite resolution on the pressure signal. Frequency response is also typically limited only by the end user's system. All products are designed and manufactured according to ISO 9001.

DIFFERENTIATION

Stability and reliability you can count on

• Industry-leading accuracy down to ±0.15 %FSS BFSL

• Port and housing options simplify integration

• Wide pressure range from±2.5 mbar to ±10 bar,

±250 Pa to ±1 MPa,

±1 in H2O to ±150 psi

• Small package size

• Low power consumption

FEATURES

Industry-leading long-term stability

Even after long-term use and thermal extremes, these sensors perform substantially better relative to stability than any other pressure sensor available in the industry today:

• Minimizes system calibration and design needs and maximizes system performance

• Helps support system uptime by eliminating the need to service or replace the sensor during its application life

• Simplifies product integration

• Supports system uptime

Industry-leading accuracy

Extremely tight accuracy down to ±0.15 %FSS BFSL:

• Reduces software needed to correct system inaccuracies, minimizing system design time

• Supports system accuracy and warranty requirements

Industry-leading flexibility

• Modular, flexible design with numerous package styles, pressure ports, and options simplifies integration into the device manufacturer's application

• Single side wet media allows the end customer to use one port of the sensor with condensing humidity or directly with non-corrosive liquid media

Insensitive to mounting orientation

Allows flexibility of use within the application.

Small size

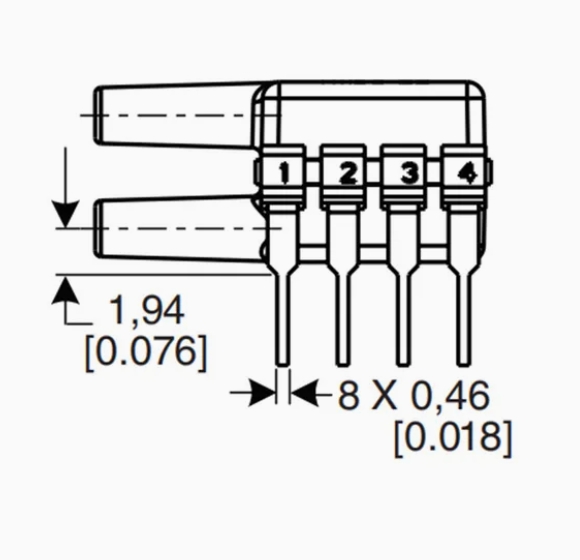

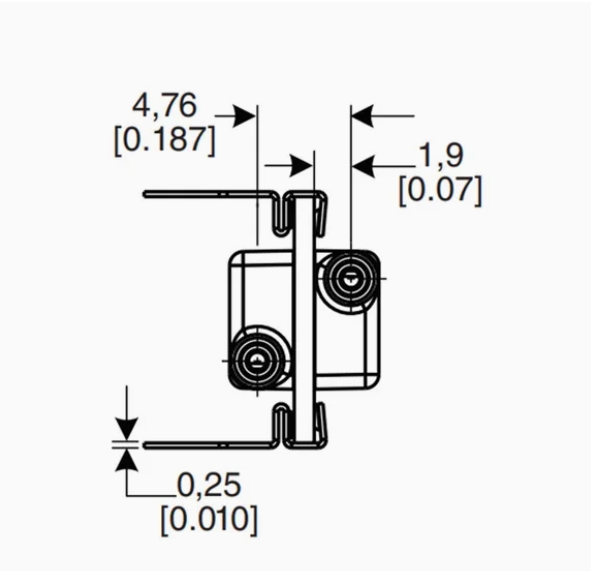

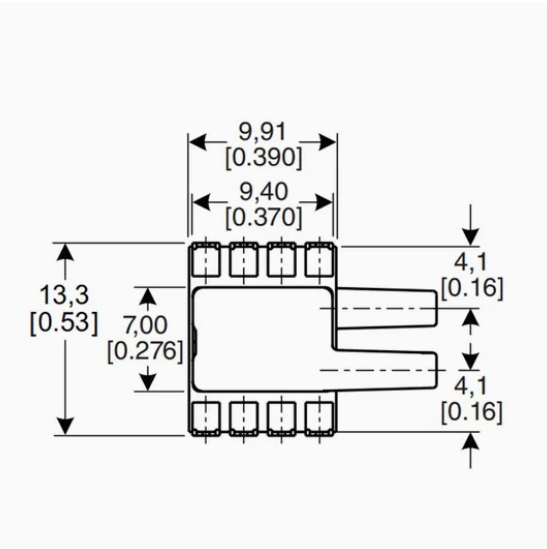

Miniature 10 mm x 10 mm [0.39 in x 0.39 in] package is very small when compared to most board mount pressure sensors:

• Occupies less area on the PCB

• Typically allows for easy placement on crowded PCBs or in small devices

Repeatability

Provides excellent repeatability, high accuracy and reliability under many demanding conditions

Supports lean manufacturing

• J-STD-020E MSL 2 with unlimited Storafe life when stored inside the moisture barrier bag

• System can be calibrated within one hour after reflow solder

• Compatible with modern lead-free and no-clean solder processes

Extremely low power consumption

• Operating supply voltage as low as 1.5 Vdc

• Reduces power consumption, provides extended battery life, and promotes energy efficiency

Absolute, differential and gage types

• Provides flexibility of use within the application

• Absolute type on NSC Series only

Pressure ranges from ±2.5 Mbar to ±10 bar | ±250 Pa to ±1 MPa | ±1 inH2O to ±150 psi

Optimizes the customer's system performance by maximizing pressure resolution with more available pressure ranges

RoHS and ISO9001 compliance

APPLICATIONS

Medical

• Nebulizers

• Spirometers

• Patient monitoring equipment

• Therapeutic hospital beds

• Hospital gas supply

• Oxygen concentrators

• Blood analysis

• Gas chromatography

• Analytical instruments

Industrial

• Valves

• Pumps

• Actuators

• HVAC transmitters

• Automated pneumatic assembly Equipment

• Pneumatic operator control systems

• Industrial gas supply

• Barometry

• Gas chromatography

• Analytical instrument Sampling systems

Tech Specifications

| Description | Product Attribute |

|---|---|

| Manufacturer | Honeywell |

| Product Category | Board Mount Pressure Sensors |

| Series | NSC |

| Product Type | Board Mount Pressure Sensors |

| Subcategory | Sensors |

| Tradename | TruStability |

| Characteristic | Min. | Max. | Unit | ||||||

| Supply voltage (Vsupply)2: pressure ranges >60 mbar | 6 kPa 1 psi pressure ranges ≤40 mbar | 4 kPa | 20 in H2O | -12.00 | 12.07 | Vdc | ||||||

| Storage temperature | -40 [-40] | 85 [185] | °C [°F] | ||||||

| Soldering time and temperature: lead solder temperature(SIP, DIP) peak reflow temperature (SMT) | 4 s max. at 250°C [482°F]15 s max. at 250°C [482°F] | ||||||||

1Absolute maximum ratings are the extreme limits the device will withstand without damage.

2Incorrect application of supply voltage or ground to the wrong pin may cause electrical failure.

TABLE 2. OPERATING SPECIFICATIONS

| Characteristic | Min. | Typ. | Max. | Unit | |||||

| Supply voltage (Vsupply):1, 2 pressure ranges >60 mbar6 kPa | 1 psi pressure ranges ≤40 mbar | 4 kPa | 20 H2O | 1.52.7 | 5.05.0 | 12.06.5 | Vdc | |||||

| Supply current (at 5.0 Vdc supply) TSC Series NSC Series | 0.61.5 | 12.2 | mA | ||||||

| Operating temperature range3 | -40[-40] | __ | 85 [185] | ºC [ºF] | |||||

| TSC Series compensated temperature range4 | 0 [32º] | __ | 85 [185] | ºC [ºF] | |||||

| Startup time | 5 | ms | |||||||

| TSC Series output resistance | __ | 2.5 | __ | kOhm | |||||

1Ratiometricity of the sensor (the ability of the device output to scale to the supply voltage) is achieved within the specified operating voltage.

2Incorrect application of supply voltage or ground to the wrong pin may cause electrical failure.

3Operating temperature range: The temperature range over which the sensor will produce an output proportional to pressure.

4Compensated temperature range: The temperature range over which the sensor will produce an output proportional to pressure within the specified performance limits.

TABLE 3. ENVIRONMENTAL SPECIFICATIONS

| Characteristic | Parameter | ||||||||

| Humidity | 0% to 95% RH, non-condensing | ||||||||

| Vibration | MIL-STD-202G, Method 204D, Condition B (15 g, 10 Hz to 2 kHz) | ||||||||

| Shock | MIL-STD-202G, Method 213B, Condition C (100 g, 6 ms duration) | ||||||||

| Life1 | 1 million pressure cycles minimum | ||||||||

| Shelf Life | Unlimited storage life, inside sealed moisture barrier bag | ||||||||

| Floor Life2 | One year floor life, after removal from sealed moisture bag, <30ºC & <60 %RH | ||||||||

| Solder reflow | J-STD-020E MSL2 (see shelf life/floor life) | ||||||||

1Life may vary depending on specific application in which the sensor is utilized.

2 Floor life, the maximum recommended time period after removal from a moisture barrier bag or dry storage prior to solder reflow. If the maximum recommended floor time is exceeded parts may require to be baked at 85°C for up to 12 hours prior to solder reflow.

BNSENS (Nanjing) Sensor Technology Co., Ltd. is located in Nanjing, China. It is a high-tech enterprise specializing in the development, manufacturing and trade of sensor products. The company has brought together a group of outstanding technical experts in various fields such as automation, electronics, machinery and computers. All employees of the company have college degrees or above. It adopts the world-class management and operation model and 6 sigma quality system. At present, the company's main products are pressure, liquid level, flow, current, switches, etc. The company's users are all over the country, and some products have been exported to Japan, South Korea and Southeast Asia.

Since its inception, the company has been based on the technical accumulation and management standards of American sensor giants. It is composed of senior engineers and managers who have served in multinational companies for many years, and has rapidly developed various pressure sensors, transmitters, liquid level, flow meters, pressure switches, digital meters, current sensors, proximity switches and other products. After years of unremitting efforts, it has become one of the leading suppliers in the domestic automation industry. Our pressure transmitters can achieve an accuracy of more than 3/10, 000. The products have been widely used in oil, natural gas, electricity, chemical industry, metallurgy, building materials, food, light industry, environmental protection, aerospace, tap water, municipal and other industries.

It is a sensor science and technology innovation company that masters the core technology of MEMS chips. The company has a research and development center in Minnesota, USA. The leader is Dr. Pan Hanjin, a famous scientist in the sensor industry. Dr. Pan Hanjin has been deeply involved in the sensor industry for more than 20 years and is an expert in the sensor industry.

The company has a number of ASIC chips independently developed, which are widely used in industrial, automotive, home appliance and other markets.

BNSENS (Nanjing) Sensing Technology Co., Ltd. is a strategic partner of Honeywell in China. The two parties proposed a plan of East serving East and jointly developed several sensors specifically for the Chinese market. These sensors will be widely used in intelligent manufacturing, Internet of Things, artificial intelligence, and smart home fields. These sensors include: Magnetic sensors, temperature sensors, humidity sensors, force sensors, fire water pressure sensors, equipment vibration sensors, human body status monitoring sensors, motion sensors, etc.

History of BNSENS Company:

BNSENS is a company focusing on sensors, instruments, and electronic components. We are a young company, founded in 1999, just 25 years old, and we are still growing.

1999: The company's first pressure sensor was launched, mainly for the petroleum and petrochemical industries.

2002: The company expanded its product line and launched temperature sensors

2005: Started producing high-precision pressure sensors for the test and measurement market

2006: Became an official authorized agent of Honeywell

2009: Introduced the Six Sigma management system, and the product qualification rate was greatly improved

2010: Became a supplier of Emerson

2011: We started selling SICK sensors

2014: Introduced the sensor production line from Germany, developed more industrial control sensors, and cooperated with TSMC

2015: Cooperated with Siemens in Vietnam

2017: The factory moved to Nanjing High-tech Zone

2019: Became a national high-tech enterprise in China

2023: We started selling products from Infineon and Rohm

BNSENS, The Future Starts Here.