GIK50R02-5

Product Description

ApplicationThe gas/air ratio regulators GIK and GI serve to maintain a constant air-gas ratio and to regulate the gas pressure upstream of gas burners on installations without preheated combustion air.

GIK and GI for modulating control, GIK..B with bypass for high/low/off control. Zero-pressure regulation with conversion kit.

Features

- With spring for compensating for the weight of the diaphragm assembly in the case of modulating control.

- Gas/air ratio regulator with inlet pressure compensationdiaphragmand zero shut-off.

- The GIK can be converted to the GIK..B. The bypass screw must be exchanged for this purpose.

Function

The gas/air ratio regulator is activated by the pressure of the combustion air line. It regulates the gas outlet pressure in the ratio 1:1 to the air control pressure.The burner capacity is varied with the aid of the air control valve.

Furnace pressure fluctuations have the same effect on gas and air throughput, thus meaning that the gas-air mixture does not change.

The low fire rate can be set by adjusting the regulator spring.

In the case of high/low control (GIK..B), the spring should be fully relaxed. The min. flow flows only through the bypass.

The setting at high fire is performed via orifices or valves on the burner

Technical data

GIK, GI

Type of gas: Natural gas, town gas, LPG (gaseous), biologically produced methane, GIK..L, GI..L only for air.

Max. inlet pressure: 3 psig (200 mbar). Combustion air control pressure: 0.2 to 48 "WC (0.5 to 120 mbar).

Outlet pressure: 0.08 to 47.5 "WC (0.2 to 119 mbar).

Differential pressure between inlet pressure pe and outlet pressure pa: max. 40 "WC (100 mbar).

Transmission ratio: 1:1.

Bypass diameter GIK..B: GIK 15-25: standard 0.06 inch (1.5 mm), possible up to 0.157 inch (4 mm)

GIK 40-50: standard 0.197 inch (5 mm), possible up to 0.354 inch (9 mm).

Adjusting range at min. flow: -1.2 to +1.2 "WC (-3 to +3 mbar)

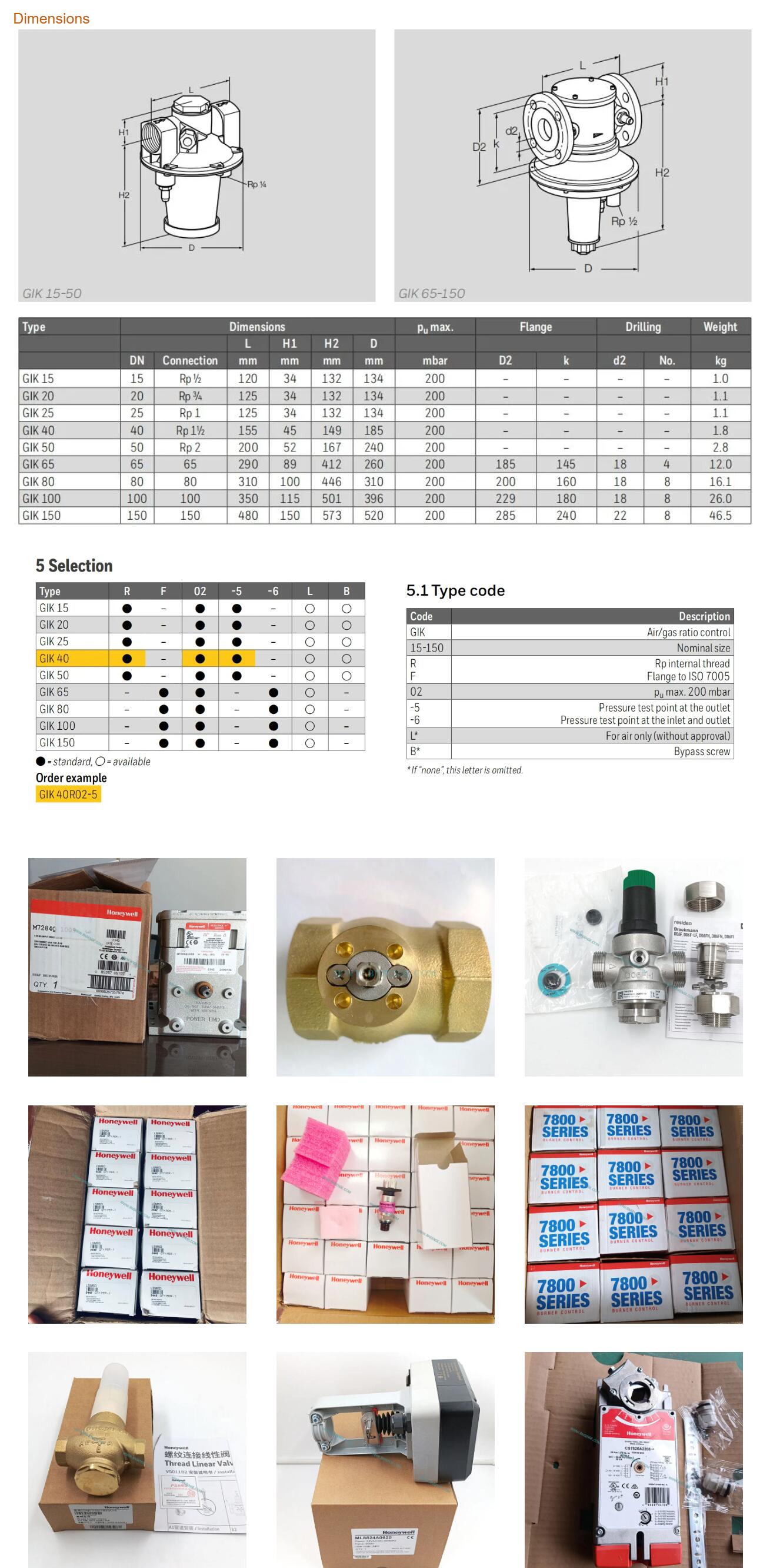

1 Adjusting screw

2 Connection for air control pressure

3 Test point for air control pressure

4 Bypass screw

5 Test point for outlet pressure

Ambient conditions

Icing, condensation and dew in and on the unit are not permitted.

Avoid direct sunlight or radiation from red-hot surfaces on the unit. Note the maximum medium and ambient temperatures!

Avoid corrosive influences, e.g. salty ambient air or SO2. The unit may only be stored/installed in enclosed rooms/buildings.

Long-term use in the upper ambient temperature range accelerates the ageing of the elastomer materials and reduces the service life (please contact manufacturer).

This unit is not suitable for cleaning with a high-pressure cleaner and/or cleaning products.

Ambient temperature:

GIK 15-50: -20 to +60°C,

GIK 65-150: -15 to +60°C,

GIKH 25: -20 to +60°C.

Storage temperature: GIK 15-50: -20 to +40°C,

GIK 65-150: -15 to +40°C,

GIKH 25: -20 to +40°C.

Transport temperature = storage temperature.

Mechanical data

Gas types: town gas, natural gas, LPG (gaseous) and biogas (max. 0.02 %-by-vol. H2S). GIK..L/ GIKH..L for air only. The gas must be clean and dry in all temperature conditions and must not contain condensate.

Medium temperature = ambient temperature.

GIK

The inlet pressure pu must be greater than the control pressure psa plus the pressure drop Δp. Max. pressure drop Δp = 100 mbar.Air control pressure: 0.5 to 120 mbar.Outlet pressure: 0.2 to 119 mbar.Gas/air pressure ratio: 1:1.

Turndown: 1:10.

Rp internal thread pursuant to ISO 7-1 and NPT internal thread.

ISO flange pursuant to ISO 7005 (PN 16) and ANSI flange.

Housing: AlSi.

Diaphragms: NBR.

Bypass screw: brass.

GIK 15-25 bypass orifice: standard Ø 1.5 mm, up to Ø 4 mm possible.

GIK 40-50 bypass orifice: standard Ø 5 mm, up to Ø 9 mm possible.

GIK 15-50

Adjusting range at low fire: -3 to +3 mbar.

Connection for control line: Rp 1/4.

Valve plate: plastic.

Valve plate seal: NBR.

GIK 65-150

Adjusting range at low fire: -2 to +2 mbar.

Connection for control line: Rp 1/2.

Valve plate: aluminium.

Valve plate seal: vulcanized NBR seal.

BNSENS (Nanjing) Sensor Technology Co., Ltd. is located in Nanjing, China. It is a high-tech enterprise specializing in the development, manufacturing and trade of sensor products. The company has brought together a group of outstanding technical experts in various fields such as automation, electronics, machinery and computers. All employees of the company have college degrees or above. It adopts the world-class management and operation model and 6 sigma quality system. At present, the company's main products are pressure, liquid level, flow, current, switches, etc. The company's users are all over the country, and some products have been exported to Japan, South Korea and Southeast Asia.

Since its inception, the company has been based on the technical accumulation and management standards of American sensor giants. It is composed of senior engineers and managers who have served in multinational companies for many years, and has rapidly developed various pressure sensors, transmitters, liquid level, flow meters, pressure switches, digital meters, current sensors, proximity switches and other products. After years of unremitting efforts, it has become one of the leading suppliers in the domestic automation industry. Our pressure transmitters can achieve an accuracy of more than 3/10, 000. The products have been widely used in oil, natural gas, electricity, chemical industry, metallurgy, building materials, food, light industry, environmental protection, aerospace, tap water, municipal and other industries.

It is a sensor science and technology innovation company that masters the core technology of MEMS chips. The company has a research and development center in Minnesota, USA. The leader is Dr. Pan Hanjin, a famous scientist in the sensor industry. Dr. Pan Hanjin has been deeply involved in the sensor industry for more than 20 years and is an expert in the sensor industry.

The company has a number of ASIC chips independently developed, which are widely used in industrial, automotive, home appliance and other markets.

BNSENS (Nanjing) Sensing Technology Co., Ltd. is a strategic partner of Honeywell in China. The two parties proposed a plan of East serving East and jointly developed several sensors specifically for the Chinese market. These sensors will be widely used in intelligent manufacturing, Internet of Things, artificial intelligence, and smart home fields. These sensors include: Magnetic sensors, temperature sensors, humidity sensors, force sensors, fire water pressure sensors, equipment vibration sensors, human body status monitoring sensors, motion sensors, etc.

History of BNSENS Company:

BNSENS is a company focusing on sensors, instruments, and electronic components. We are a young company, founded in 1999, just 25 years old, and we are still growing.

1999: The company's first pressure sensor was launched, mainly for the petroleum and petrochemical industries.

2002: The company expanded its product line and launched temperature sensors

2005: Started producing high-precision pressure sensors for the test and measurement market

2006: Became an official authorized agent of Honeywell

2009: Introduced the Six Sigma management system, and the product qualification rate was greatly improved

2010: Became a supplier of Emerson

2011: We started selling SICK sensors

2014: Introduced the sensor production line from Germany, developed more industrial control sensors, and cooperated with TSMC

2015: Cooperated with Siemens in Vietnam

2017: The factory moved to Nanjing High-tech Zone

2019: Became a national high-tech enterprise in China

2023: We started selling products from Infineon and Rohm

BNSENS, The Future Starts Here.