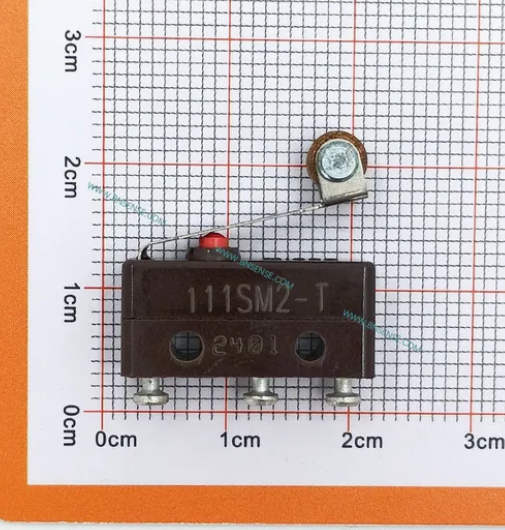

111SM2-T

Specifications

| Description | Product Attribute |

|---|---|

| Manufacturer | Honeywell |

| Product Category | Basic / Snap Action Switches |

| Series | SM |

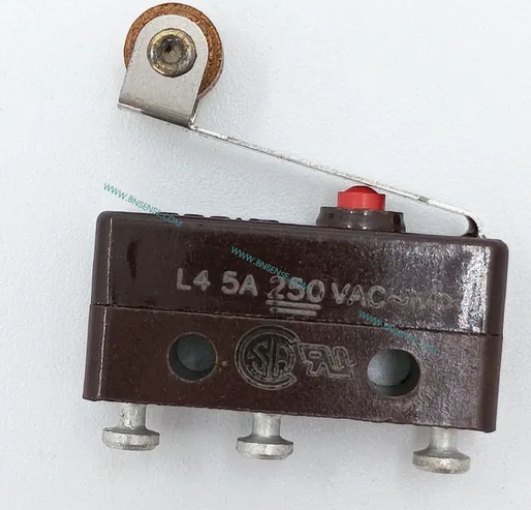

| Type | Micro Switch |

| Contact Form | SPDT |

| Switch Function | ON - (OFF), OFF - (ON) |

| Actuator | Roller Lever |

| Current Rating | 5 A |

| Voltage Rating AC | 250 VAC |

| Voltage Rating DC | 30 VDC |

| Operating Force | 2 N |

| Termination Style | Solder Turret |

| Mounting Style | Chassis Mount |

| Actuator Style | Roller Lever |

| Compliance | UL; CE; CSA; ENEC |

| Contact Material | Silver |

| Illuminated | Non-Illuminated |

| Maximum Operating Temperature | + 125 C |

| Minimum Operating Temperature | - 55 C |

| Product Type | Snap Action Switches |

| Subcategory | Switches |

Product Description

The industry-defining name in snap-action switches, Honeywell MICRO SWITCH premium subminiature switches are designed for repeatability and enhanced product life. The MICRO SWITCH SM Series delivers consistent performance within a range of conditions. The MICRO SWITCH SM Series' small size and light weight are combined with ample electrical capacity, precision operation, and extended life. Featuring high precision and repeatability, the SM Series offers gold contacts for low-energy switching and gold bifurcated contacts for maximum reliability. Bifurcated contacts provide parallel redundancy within the SM switch. The SM switch is available for power-duty switching up to 11 A (Vac) or 1/4 HP (Vac).

DIFFERENTIATION

• Very wide temperature range allows for years of reliable performance in the harshest of conditions

• MIL-PRF-8805 qualified listings

• Operating forces as low as 0,06 N [6 g] and differential travel as low as 0,025 mm [0.001 in] delivers consistent, precise switch characteristics

FEATURES

• Industry-leading mechanical life of up to 10,000,000 operations

• Selection of actuation, electrical termination, and operating characteristics along with high-temperature construction options

• Wide temperature range of -54°C to 204°C [-65°F to 400°F]

• MIL-PRF-8805 qualified listings in a lightweight, small package

• FAA-PMA approvals for commercial aircraft

• Choice of silver or gold-plated, or gold bifurcated contacts to handle a variety of electrical load requirements

• UL/CSA, cUL, ENEC, and CE approvals

VALUE TO CUSTOMERS

• Industry-leading life cycle rating reduces the need to replace switches over life in an OEM platform - reducing total system cost

• Low operating forces

• Mil-qualified listings

• Life of up to 10,000,000 cycles

POTENTIAL APPLICATIONS

• Precision switch assemblies for commercial aircraft to monitor doors for "closed" and "locked" position

• Landing gear monitor

• Precision switch assemblies for commercial cockpit applications for pushbuttons, toggle, or joystick assemblies

• Precision switch assemblies in military applications

• Assemblies for industrial pressure switches and temperature switches

• Power generation fuel level (gas and oil)

PORTFOLIO

The SM Series of premium subminiature basic switches are a part of a strong offering of submins including SX Series (premium) and ZM, ZM1, ZD, ZX, and ZW Series (standard) switches.

| MICRO SWITCH SM Series Order Guide • Pin Plunger | O. F. • Operating forceR. F. • Release forceP.T. • PretravelO.T. • OvertravelD.T. • Differential travelO. P. • Operating position | |||||||||

| CatalogListing | Recommended For | Electrical | Data and ULCodes | O.F.N [oz] | R.F. min.N [ oz] | P.T. max.mm [in] | O.T. min.mm [in] | D.T.mm [in] | O.P. *mm [in] | |

| 11SM1077-T | Gold-plated contacts | 0.1 AP | 0,83 to 1,39[3 to 5] | 0,28 [1] | 0,51[0.020] | 0,13[0.005] | 0,1 [0.004] | 8,38[0.330] | ||

| 12SM604-T | Bifurcated gold contacts,reduced rating | 0.1 AP | 0,83 to 1,39[3 to 5] | 0,28 [1] | 0,51[0.020] | 0,076[0.003] | 0,1 [0.004] | 8,38[0.330] | ||

| 11SM23-T | Gold-plated contacts | 1 AN | 0,83 to 1,39[3 to 5] | 0,28 [1] | 0,51[0.020] | 0,13[0.005] | 0,1 [0.004] | 8,38[0.330] | ||

| 12SM4-T | Enhanced reliability(bifurcated gold contacts) | 1 AN | 0,83 to 1,39[3 to 5] | 0,28 [1] | 0,51[0.020] | 0,076[0.003] | 0,1 [0.004] | 8,38[0.330] | ||

| 11SM701-T | Lower force | 4 AS | 0,56 [2] | 0,14 [0.5] | 0,51[0.020] | 0,13[0.005] | 0,051[0.002] | 8,38[0.330] | ||

| 11SM1-T | General purpose | 5 AJ | 0,83 to 1,39[3 to 5] | 0,28 [1] | 0,51[0.020] | 0,13[0.005] | 0,1 [0.004] | 8,38[0.330] | ||

| 11SM3-T | Operating temps to 121°C[250°F] | 5 AJ | 0,83 to 1,39[3 to 5] | 0,28 [1] | 0,51[0.020] | 0,13[0.005] | 0,1 [0.004] | 8,38[0.330] | ||

| 11SM244-T | Operating temps to 204°C[400°F] for 100 hours | 5 A | 0,83 to 1,39[3 to 5] | 0,28 [1] | 0,51[0.020] | 0,13[0.005] | 0,1 [0.004] | 8,38[0.330] | ||

| 11SM401-T | Less differential travel | 5 AK | 0,97 [3.5]max. | 0,28 [1] | 0,51[0.020] | 0,13[0.005] | 0,025[0.001] | 8,38[0.330] | ||

| 21SM284-T2(MS25085-2) | MIL-PRF-8805applications | 5 AR | 0,83 to 1,39[3 to 5] | 0,28 [1] | 0,76[0.030] | 0,13[0.005] | 0,1 [0.004] | 8,38[0.330] | ||

| 21SM284(MS25085-1) | MIL-PRF-8805applications, solderterminals | 5 AR | 0,83 to 1,39[3 to 5] | 0,28 [1] | 0,76[0.030] | 0,13[0.005] | 0,1 [0.004] | 8,38[0.330] | ||

| 22SM1-T | Enhanced stability undervarying humidity | 5 AJ | 0,83 to 1,39[3 to 5] | 0,28 [1] | 0,51[0.020] | 0,13[0.005] | 0,1 [0.004] | 8,38[0.330] | ||

| 41SM1-T | Up to 11 A, 1/4 HP (ac) | 11 AM | 0,83 to 1,39[3 to 5] | 0,28 [1] | 0,76[0.030] | 0,13[0.005] | 0,1 [0.004] | 8,38[0.330] | ||

| 411SM1 | Sealed plunger construction | 5 AK | 0,83 to 2,09[3 to 7.5] | 0,28 [1] | 0,51[0.020] | 0,13[0.005] | 0,1 [0.004] | 8,38[0.330] | ||

| 411SM23 | Sealed plunger construc-tion, gold contacts | 1 AN | 0,83 to 2,09[3 to 7.5] | 0,28 [1] | 0,51[0.020] | 0,13[0.005] | 0,1 [0.004] | 8,38[0.330] | ||

* except where stated ±0,38 mm [±0.015 in]

| MICRO SWITCH SM Series Order Guide • Integral Lever | O. F. • Operating forceR. F. • Release forceP.T. • PretravelO.T. • OvertravelD.T. • Differential travelO P • Operating | ||||||||||

| CatalogListing | Recommended For | Electrical | Data and | UL Codes | O.F.N [oz] | R.F.min.N [ oz] | P.T. max.mm [in] | O.T. min.mm [in] | D.T.mm [in] | O.P. *mm [in] | |

| 311SM1-T | 7,24 mm [0.285 in] straightlever | 5 AJ | 0,39[1.4] | 0,07[0.25] | 2,16[0.085] | 0,51[0.020] | 0,48[0.019] | 8,64 mm ±1,5 mm[0.34 in ±0.060 in] | |||

| 311SM23-T | 7,24 mm [0.285 in] straightlever, gold contacts | 1 AN | 0,39[1.4] | 0,07[0.25] | 2,16[0.085] | 0,51[0.020] | 0,48[0.019] | 8,64 mm ±1,5 mm[0.34 in ±0.060 in] | |||

| 311SM701-T | 7,24 mm [0.285 in] straightlever, lower force | 4 AS | 0,16[0.57] | 0,03[0.11] | 2,16[0.085] | 0,51[0.020] | 0,36[0.014] | 8,64 mm ±1,5 mm[0.34 in ±0.060 in] | |||

| 311SM2-T | 14,35 mm [0.565 in] straightlever | 5 AJ | 0,31[1.1] | 0,05[0.18] | 3,05[0.12] | 0,66[0.026] | 0,69[0.027] | 8,51 mm ±2 mm[0.335 in ±0.08 in] | |||

| 311SM43-T | 14,35 mm [0.565 in] straightlever, gold contacts | 1 AN | 0,31[1.1] | 0,05[0.18] | 3,05[0.12] | 0,66[0.026] | 0,69[0.027] | 8,51 mm ±2 mm[0.335 in ±0.08 in] | |||

| 311SM702-T | 14,35 mm [0.565 in] straightlever, lower force | 4 AS | 0,11[0.4] | 0,02[0.07] | 3,05[0.12] | 0,66[0.026] | 0,38[0.015] | 8,51 mm ±2 mm[0.335 in ±0.08 in] | |||

| 311SM3-T | 44,8 mm [1.765 in] straightlever | 5 AJ | 0,15[0.53] | 0,02[0.07] | 7,87[0.31] | 1,45[0.057] | 2,8[0.11] | 7,11 mm ±4,3 mm[0.28 in ±0.17 in] | |||

| 311SM17-H58 | 44,8 mm [1.765 in] straightlever, gold contacts | 1 AN | 0,15[0.53] | 0,02[0.07] | 7,87[0.31] | 1,45[0.057] | 2,8[0.11] | 7,11 mm ±4,3 mm[0.28 in ±0.17 in] | |||

| 311SM703-T | 44,8 mm [1.765 in] straightlever, lower force | 4 AS | 0,06[0.2] | 0,01[0.04] | 7,87[0.31] | 1,45[0.057] | 1,78[0.07] | 7,11 mm ±4,3 mm[0.28 in ±0.17 in] | |||

| 311SM4-T | 6,38 mm [0.251 in] simulat-ed roller lever | 5 AJ | 0,39[1.4] | 0,07[0.25] | 2,16[0.085] | 0,46[0.018] | 0,48[0.019] | 11,7 mm ±1,5 mm[0.46 in ±0.06 in] | |||

| 311SM25-T | 6,38 mm [0.251 in] simu- latedroller lever, gold contacts | 1 AN | 0,39[1.4] | 0,07[0.25] | 2,16[0.085] | 0,46[0.018] | 0,48[0.019] | 11,7 mm ±1,5 mm[0.46 in ±0.06 in] | |||

| 311SM704-T | 6,38 mm [0.251 in] simulat-ed roller lever, lower force | 4 AS | 0,16[0.57] | 0,03[0.11] | 2,16[0.085] | 0,46[0.018] | 0,33[0.013] | 11,7 mm ±1,5 mm[0.46 in ±0.06 in] | |||

| 311SM5-T | 13,6 mm [0.535 in] simulat-ed roller lever | 5 AJ | 0,31[1.1] | 0,05[0.18] | 3,05[0.12] | 0,66[0.026] | 0,69[0.027] | 11,56 mm ±2 mm[0.455 in ±0.08 in] | |||

| 311SM705-T | 13,6 mm [0.535 in] simulat-ed roller lever, lower force | 4 AS | 0,11[0.4] | 0,02[0.07] | 3,05[0.12] | 0,66[0.026] | 0,38[0.015] | 11,56 mm ±2 mm[0.455 in ±0.08 in] | |||

| 311SM6-T | 6,38 mm [0.251 in] rollerlever | 5 AJ | 0,39[1.4] | 0,07[0.25] | 2,16[0.085] | 0,46[0.018] | 0,48[0.019] | 14,2 mm ±1,5 mm[0.56 in ±0.06 in] | |||

| 311SM68-T | 6,38 mm [0.251 in] rollerlever, gold contacts | 1 AN | 0,39[1.4] | 0,07[0.25] | 2,16[0.085] | 0,46[0.018] | 0,48[0.019] | 14,2 mm ±1,5 mm[0.56 in ±0.06 in] | |||

| 311SM706-T | 6,38 mm [0.251 in] rollerlever, lower force | 4 AS | 0,16[0.57] | 0,03[0.11] | 2,16[0.085] | 0,46[0.018] | 0,33[0.013] | 14,2 mm ±1,5 mm[0.56 in ±0.06 in] | |||

| 311SM7-T | 13,6 mm [0.535 in] rollerlever | 5 AJ | 0,31[1.1] | 0,05[0.18] | 3,05[0.12] | 0,66[0.026] | 0,69[0.027] | 14,1 mm ±2 mm[0.555 in ±0.08 in] | |||

| 111SM1-T | Leaf actuator | 5 AJ | 1,95[7] | 0,56[2] | 5,54[0.218] | 0,76[0.03] | 0,76[0.03] | 8,89 mm ±0,76 mm[0.35 in ±0.03 in] | |||

| 111SM17-T | Leaf actuator gold contacts | 1 AN | 1,95[7] | 0,56[2] | 5,54[0.218] | 0,76[0.03] | 0,76[0.03] | 8,89 mm ±0,76 mm[0.35 in ±0.03 in] | |||

| 111SM2-T | Flexible leaf with roller | 5 AJ | 1,95[7] | 0,56[2] | 5,56[0.219] | 0,76[0.03] | 0,64[0.025] | 14,3 mm ±0,76 mm[0.562 in ±0.03 in] | |||

| 111SM23-T | Flexible leaf with roller, goldcontacts | 1 AN | 1,95[7] | 0,56[2] | 5,56[0.219] | 0,76[0.03] | 0,64[0.025] | 14,3 mm ±0,76 mm[0.562 in ±0.03 in] | |||

| Electrical data and UL codes | |||

| UL Electrical Ratings | |||

| Code | Circuitry | Electrical data and UL codes | |

| J | SPDT | 5 A res., 3 A ind., (sea level),5 A res., 2.5 A ind., (50,000 feet), 28 Vdc. UL rating: 5 A, 250 Vac | |

| K | SPDT | UL rating: 5 A, 125 or 250 Vac | |

| M | SPDT | UL rating: 11 A and 1/4 hp, 125 or 250 Vac | |

| N | SPDT | 1 A res., 0.5 A ind., 30 Vdc. UL rating: 1 A, 125 Vac | |

| P | SPDT | 1 A res., 30 Vdc. UL rating: .1 A, 125 Vac | |

| R | SPDT | 5 A res., 3 A ind., 2.4 A lamp load (sea level),5 A res., 2.5 A ind., 2.4 A lamp load, (50,000 feet), 28 Vdc.5 A res., 5 A ind., 1.5 A lamp load, 115 Vac. 60 Hz (sea level) | |

| S | SPDT | UL rating: 4 A, 250 Vac | |

BNSENS (Nanjing) Sensor Technology Co., Ltd. is located in Nanjing, China. It is a high-tech enterprise specializing in the development, manufacturing and trade of sensor products. The company has brought together a group of outstanding technical experts in various fields such as automation, electronics, machinery and computers. All employees of the company have college degrees or above. It adopts the world-class management and operation model and 6 sigma quality system. At present, the company's main products are pressure, liquid level, flow, current, switches, etc. The company's users are all over the country, and some products have been exported to Japan, South Korea and Southeast Asia.

Since its inception, the company has been based on the technical accumulation and management standards of American sensor giants. It is composed of senior engineers and managers who have served in multinational companies for many years, and has rapidly developed various pressure sensors, transmitters, liquid level, flow meters, pressure switches, digital meters, current sensors, proximity switches and other products. After years of unremitting efforts, it has become one of the leading suppliers in the domestic automation industry. Our pressure transmitters can achieve an accuracy of more than 3/10, 000. The products have been widely used in oil, natural gas, electricity, chemical industry, metallurgy, building materials, food, light industry, environmental protection, aerospace, tap water, municipal and other industries.

It is a sensor science and technology innovation company that masters the core technology of MEMS chips. The company has a research and development center in Minnesota, USA. The leader is Dr. Pan Hanjin, a famous scientist in the sensor industry. Dr. Pan Hanjin has been deeply involved in the sensor industry for more than 20 years and is an expert in the sensor industry.

The company has a number of ASIC chips independently developed, which are widely used in industrial, automotive, home appliance and other markets.

BNSENS (Nanjing) Sensing Technology Co., Ltd. is a strategic partner of Honeywell in China. The two parties proposed a plan of East serving East and jointly developed several sensors specifically for the Chinese market. These sensors will be widely used in intelligent manufacturing, Internet of Things, artificial intelligence, and smart home fields. These sensors include: Magnetic sensors, temperature sensors, humidity sensors, force sensors, fire water pressure sensors, equipment vibration sensors, human body status monitoring sensors, motion sensors, etc.

History of BNSENS Company:

BNSENS is a company focusing on sensors, instruments, and electronic components. We are a young company, founded in 1999, just 25 years old, and we are still growing.

1999: The company's first pressure sensor was launched, mainly for the petroleum and petrochemical industries.

2002: The company expanded its product line and launched temperature sensors

2005: Started producing high-precision pressure sensors for the test and measurement market

2006: Became an official authorized agent of Honeywell

2009: Introduced the Six Sigma management system, and the product qualification rate was greatly improved

2010: Became a supplier of Emerson

2011: We started selling SICK sensors

2014: Introduced the sensor production line from Germany, developed more industrial control sensors, and cooperated with TSMC

2015: Cooperated with Siemens in Vietnam

2017: The factory moved to Nanjing High-tech Zone

2019: Became a national high-tech enterprise in China

2023: We started selling products from Infineon and Rohm

BNSENS, The Future Starts Here.